Pick FireFoxxAuto LLC in Salt Lake City for dependable, inspection-backed metal fabrication. We provide CMM-verified dimensions, AWS/ISO-compliant welds, documented WPS/PQRs, and copyright-controlled processes that minimize rework and downtime. We process prototypes to production with CAD/CAM programming, fixture control, and controlled heat input to preserve flatness and squareness. Materials include 316/304 stainless, 6061-T6, and coated carbon steel, validated with DFT, adhesion, and salt-spray tests. Provide CAD, tolerances, quantities, finishes, and timeline for an itemized quote and faster kickoff you can count on.

Important Points

- Comprehensive metal fabrication in Salt Lake City offering prototyping, low-volume, and scalable production with fixed revisions and traceability.

- Precision quality controls: Coordinate measuring machine inspections, Statistical process control documentation, Welding compliant with AWS/ISO standards, and comprehensive WPS/PQR with first-article inspection approvals.

- Advanced welding and fixturing: robotic alignment, vision-guided seam tracking, distortion control, and heat input management for slender and heavy sections.

- Materials and finishes expertise: 316/304 stainless, T6-6061 aluminum, carbon steel with galvanizing and powder coat; quality-assured by salt-spray, adhesion, and DFT tests.

- Straightforward quoting and scheduling: itemized estimates, RFQ checklist, risk reviews, milestone updates, expedited options, and a single point of contact.

Why Salt Lake City Trusts FireFoxxAuto LLC for Metal Fabrication Solutions

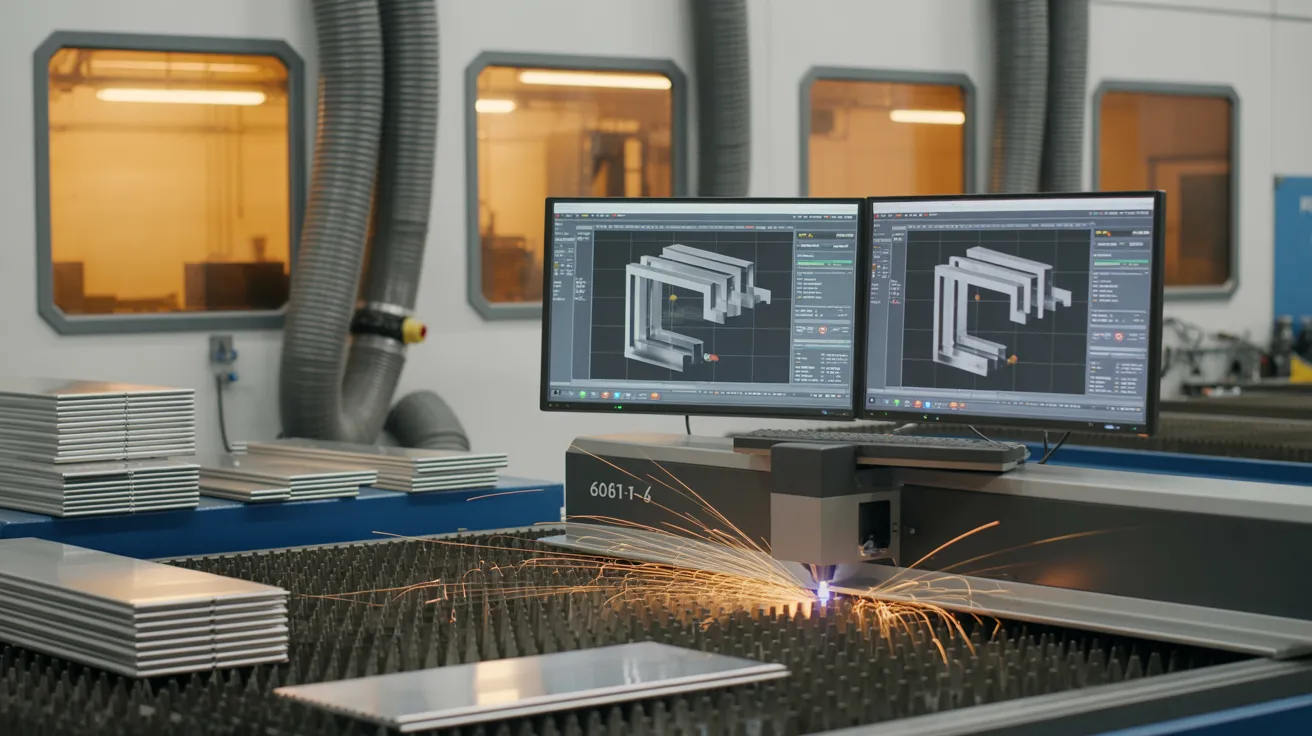

As precision is essential for every cutting and welding operation, Salt Lake City depends on FireFoxxAuto LLC for metal fabrication that achieves tight tolerances and demanding timelines. You pick them because they fine-tune processes according to specifications, check dimensions with CMM inspections, and record each phase for traceability. Their welders and machinists operate to AWS and ISO specifications, minimizing delays and rework.

Their reliability is also something you value. Lead time forecasting, critical-path operation buffering, and proactive change communication are part of their approach. Their maintenance program for tooling minimizes variance, and copyright charts identify drift prior to affecting fit-up.

FireFoxxAuto LLC commits to community partnerships that reinforce the local supply chain and workforce pipelines. You'll value their sustainable practices-closed-loop coolant systems, optimized nesting to reduce scrap, and responsible recycling-reducing costs and environmental impact.

Solutions: From Bespoke Prototypes to Manufacturing Runs

From first-article prototypes to steady-state production, FireFoxxAuto LLC expands your metal fabrication operations with the same rigor at every stage. You get a organized procedure: requirements capture, DFM review, CAD/CAM programming, material validation, and controlled fabrication. Our rapid prototyping compresses lead times with in-house cutting, forming, and CNC machining, so you can modify designs without compromising dimensional accuracy.

Once you're prepared for low volume manufacturing, we lock specifications with revision control, define process parameters, and implement copyright checks to optimize throughput. We control BOMs, traceability, and lot-level documentation to preserve consistency across repeat orders. For full production runs, we implement standard fixtures and tooling, balance cycle times, and align with your release cadence, ensuring reliable delivery, predictable costs, and reliable, compliant parts.

Accurate Welding and Strict-Tolerance Performance

You've locked specs and stabilized throughput; now the joints must meet the same rigor. You require welds that maintain dimensional accuracy under heat, load, and inspection. We deliver by regulating arc energy, travel speed, and bead geometry to ensure flatness, squareness, and parallelism across assemblies.

We integrate robotic alignment with fixture repeatability and micro tolerance calibration at every setup. Vision-guided seam tracking corrects path drift in real time, while pulsed parameters limit distortion and HAZ. For thin-gauge parts, we balance penetration against heat input to prevent warping; for thick sections, we control multi-pass sequencing to maintain tolerances.

Every weldment undergoes verification with CMM checks, profilometry, and dye penetrant as necessary. You receive reliable, high-precision results that merge smoothly downstream without rework.

Materials and Finishes That Withstand Real-World Use

Long-term performance begins with the right alloy and the correct surface system for the environment. You select materials based on load, exposure, and maintenance requirements. For coastal or deicing-salt conditions, specify 316 for outstanding Stainless corrosion resistance; for interiors or mild exposure, 304 performs effectively. When weight matters, select 6061-T6 aluminum and hardcoat anodize to increase wear resistance. For carbon steel structures, prioritize galvanizing for sacrificial protection, then apply a high-build topcoat.

You determine surface finish durability by pairing coating chemistry to service class. Powder coat performance relies on substrate prep: SSPC-SP 10 near-white blast, a zinc-rich primer, and a TGIC-polyester topcoat cured to spec. Verify with DFT readings, crosshatch adhesion, and salt-spray testing. Document callouts on drawings to guarantee repeatable performance.

Quick Turnarounds Without Compromising Quality

When facing strict deadlines, you hit dates by systematizing procedures, not taking shortcuts. You prioritize upfront planning: validate tolerances, identify alloys, secure tooling, and build CAM paths that limit tool changes and travel. You organize raw stock, fixtures, and consumables so machines function nonstop. For rapid prototyping, you regularize material thicknesses and bend radii, permitting you to reuse verified setups and arrange parts productively. You laser-cut blanks, then move to CNC forming and TIG and MIG welding with recorded WPS parameters that preserve strength and finish.

For emergency repair work, you diagnose the breakdown, evaluate worn surfaces, and engineer replacement components with coordinate measuring machines or laser scanning. You begin by machining critical surfaces, validate through in-process measurement, then complete assembly and finishing. The result: fast cycle times without sacrificing durability or fit.

Transparent Pricing and Clear Communication

Although scope evolves, pricing won't. You get granular estimates anchored in engineering drawings, tolerance classes, and material specs, so pricing transparency is integrated into your RFQ. We anchor quoted rates to defined revision levels; any change initiates a documented delta with unit, setup, and finish costs separated. No hidden surcharges—machine time, consumables, and outside processes are enumerated.

We maintain clear communication protocols that deliver information without unnecessary clutter. You receive updates at key milestones: purchase order approval, material receipt, first-article approval, in-process inspection findings, and ship confirmation including traceable heat lots. A single point of contact, response SLAs, and change-control tickets documenting approvals and timestamps are maintained. You can request CAD markups, weld maps, and CMM reports. Clear data, predictable prices, and disciplined coordination prevent surprises and rework.

Sectors We Serve: Contractors, Producers, and DIY Enthusiasts

Once pricing and communication are locked down, we adapt metal fabrication to the way you build. As a contractor, you get structural steel, brackets, handrail systems, and site-ready assemblies cut, welded, and coated to your specifications, synchronized with tight schedules and inspection requirements—ideal for long-term construction partnerships. For manufacturers, we deliver repeatable parts with press brake forming, CNC cutting, and fixture-controlled welding, supported by material traceability, PPAP-level documentation when requested, and Kanban or JIT releases to streamline your line.

DIY builders will appreciate our support for individual pieces and short runs: personalized brackets, gussets, tabs, and panel components, completed or unfinished, well-suited for garage fabrication and recreational workshops. We deliver accurate drawings, tight tolerances, and suitable metal alloys, confirming that parts match specifications, perform flawlessly, and finish precisely as required.

How to Request a Quote and Begin Your Project Today

To get an accurate quote, you'll prepare a brief scope: material grade, thickness, tolerances, quantity, CAD files (STEP/DWG), finish, and required standards. Provide drawings with dimensions, weld symbols, and callouts, together with your timeline and delivery location. Send these via the online form or email, and request detailed pricing, lead time, and any value-engineering suggestions.

What to Prepare

Before you request a quote, gather the specifics of your metal fabrication project so fabricators can quote it precisely and commence promptly. Define objectives, tolerances, and performance requirements. Provide dimensioned drawings or STEP/DWG files, weld symbols, finishes, and callouts for critical features. Specify alloys, thicknesses, certifications, and approved substitutes to facilitate material sourcing. Document required processes-laser cutting, forming, machining, welding, powder coat-and indicate any heat treatment.

Document quantities, revision level, and inspection criteria (PPAP, CMM reports, weld procedure qualifications). Define assembly interfaces, hardware, and thread specifications. Include environmental conditions, load cases, and compliance requirements (AWS standards, ASTM standards, ISO). Specify packaging, labeling, and delivery terms. Provide target budget ranges and desired project scheduling windows. Share constraints, risks, and approval gates to decrease iterations and speed up kickoff.

Requesting Your Quote

With a complete prep package, you're ready to request a quote and start production. Submit your technical drawings, tolerances, quantities, target lead time, and finish specs. Include critical dimensions, inspection criteria, and any certification requirements. Note specified alloys and acceptable equivalents to streamline material sourcing.

Upload CAD files (STEP and IGES formats) as well as PDFs. Define welding processes, heat treatment, and surface preparation. Indicate required fixturing, jigs, and any assembly procedures. Provide delivery deadlines and packaging requirements. Include cost parameters to optimize process routing.

We'll confirm manufacturability, identify risk points, and suggest revisions if needed. You'll get a complete estimate including NRE, unit pricing by volume tier, tooling, and QA. Ask about local inventory options, community outreach partnerships, and expedited scheduling. Sign off on scope, sign the SOW, and we will then finalize timeline and start production.

FAQ

Do You Provide On-Site Installation or Field Repair Services?

Yes, you get on-site installation and field repair services. Consider a pit-stop crew: we deploy, execute on site diagnostics, and get you back to spec rapidly. You'll receive precision measurements, torque-verified connections, and weld integrity checks. We perform field commissioning, alignments, PLC I/O verification, and load testing. You won't wait on shop schedules-we arrive with certified techs, stocked spares, and safety-compliant procedures to cut downtime and restore performance properly.

Which CAD File Formats Are Accepted for Designs?

We accept STEP and IGES, SolidWorks Parasolid (x_t/x_b), native SLDPRT/SLDASM, DXF for 2D profiles, and STL formats for meshes. We also accept DWG, PDF with dimensions, and DXF STEP hybrids as needed. For manufacturability, prioritize STEP for solids and DXF for flat patterns; use STL only for reference or additive. Make sure to include units, material, here tolerances, and revision. We will validate geometry, resolve import issues, and confirm critical features.

Do You Accept Rush Jobs Beyond Normal Business Hours?

Rush jobs outside normal business hours are accommodated. Need it faster? We emphasize after-hours dispatch, assemble crews, and dedicate machinery for urgent welding and accurate fabrication. You'll obtain a structured escalation system, an assigned supervisor, and instant status reports. We confirm material availability, program CNCs, and stage quality checks to compress lead time without compromising tolerances. Submit scope, drawings, and deadlines; we'll quote expedited rates and lock a completion window immediately.

Do You Provide Design-For-Manufacturability (DFM) Advisory Services?

Absolutely. You can book DFM sessions focused on design optimization and tolerance analysis. We examine material selection, manufacturable geometries, bend radii, weld access, and fixturing strategy. We validate stack-ups, specify critical-to-function tolerances, and align GD&T with process capability. You'll receive actionable revisions, lead-time and cost impacts, and suggested gauge, finish, and joining methods. We also prototype critical features to mitigate risk in production. Provide CAD, prints, and volumes; we'll scope deliverables and timeframe.

What Packaging and Shipping Options Do You Offer for Finished Parts?

Similar to a protective vault for your parts, we provide multiple packaging and shipping alternatives. You select custom crating, foam-in-place, anti-corrosion wraps, or reusable containers coordinated with geometry, finish, and transit risk. We label for traceability and include inspection certificates. For delivery, select insured freight, LTL, dedicated truckload, or expedited carriers. We palletize to ISPM-15 standards, add shock/tilt indicators on request, and supply tracking, proof of delivery, and freight claims support.

Final Thoughts

You need parts that fit, welds that hold, and timelines that remain intact. With FireFoxxAuto LLC, you get precise fabrication-from prototype to production-plus rigorous QA, durable materials and finishes, and transparent pricing. We hit tight tolerances, deliver projects rapidly without shortcuts, and keep you updated at every step. Whether you're a contractor, manufacturer, or DIY builder, we do it right the first time. Precision matters-and get a quote today to move your build forward.